INTEREST-FREE FINANCING AVAILABLE Mizutani scissor sharpening

MIZUTANI METAL mizutani shears

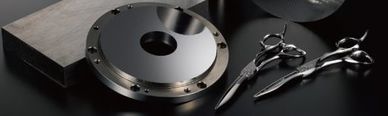

Nano Powder Metal

Our Nano Powder Metal®, made with the new HIP manufacturing method (Hot Isostatic Pressing), is steel fabricated from a fine powder at the nano level. The uniform-grained powder is hardened with high temperature and pressure tempering, essentially eliminating all filler and impurities, and this method is used in precision manufacturing items like Blu-ray disc molds, where high levels of purity are required. At MIZUTANI, in order to create the ideal hair-cutting scissors, we have conducted our own proprietary research with this material, and created scissors with blades that combine strength with a long cutting life and the ultimate sharpness.

STELLITE alloy

The Stellite® used at MIZUTANI is made by the Deloro Stellite company, and is an exceptional alloy with high levels of resistance to heat and wear and tear. The thought process behind it differs fundamentally from typical steel, and it is also called cobalt-base alloy, as that rare metal makes up more than 50% of its composition. As a result, it is a special material that never rusts. It is often used in parts of jets exposed to severe environments, and also engine components in race cars, and its use has been proven to dramatically improve the working life of engines. This is a special steel that costs more than 30 times the price point of materials used in typical edged tools. At MIZUTANI, this material is used in our highest level of premium products, the STELLITE alloy series.

POWDER DAMA

DAMA® (Powder Damascus Alloy / patented manufacturing method) is made from two different types of fine powders. Each contains different components of powdered steel, and through a complicated mixture, it is cast in a super high density form. As a result, not only the front, but also the back, and even the interior are all the same Damascus steel. This complex and laborious manufacturing method is an international patent. Also, through the special hardening technique, the two raw materials of high molybdenum alloy and high chromium alloy are combined and tempered to identical hardness. It remains sharp and effective for haircutting, even after long-term continuous usage. The rippling patterns of DAMA® are brought out and made more prominent through a proprietary processing technique. This beautiful material also features an astonishing strength, and is used for our DAMA® series.

HIGH MOLYBDENUM

High molybdenum steel alloy (patented steel material) is a tough material with excellent wear and corrosion resistance often used in products like diving knives. Because this high-molybdenum and high-chromium material doesn’t rust easily, its ease of maintenance is a notable feature. Our ACRO KNIFE product is made from this material, and it is a heavy duty model that can stand up to the most severe and demanding usage.

EXTRAMARISE

EXTRAMARISE® is a proprietary heat treatment ideally suited for haircutting scissors that was developed by MIZUTANI based on long years of accumulated data and experience. The same steel material can have totally different performance depending on the heat treatment used. Therefore, to maximize the special qualities of the rare metals (cobalt, molybdenum, vanadium, etc.) we’ve added to our products to the greatest extent possible, and achieve the ideal metal for scissors, (*hardening, tempering, sub-zero processing) and other complete temperature management procedures are essential. To bring out the distinct characteristics of materials, and manufacture a blade with the ultimate strength required for haircutting scissors, we at MIZUTANI have implemented our own proprietary heat treatment using the ideal temperature for scissors: EXTRAMARISE® processing.

MIZUTANI SINCE 1921

*Hardening, tempering, sub-zero processing:

MIZUTANI’s scissors last for 30 years, and are made using the ideal heat treatment to bring out the character of the premium materials used to manufacture them. You’ve probably heard the term “hardening” before. The steel typically used in scissors is not hard enough on its own. The stainless steel scissors used by hair stylists achieve the hardness required through high temperature processing at over 1000°C. (This process differs for Stellite® and other cobalt alloys.) Also, with just hardening, the metal is hard, but it’s also extremely brittle. Another process called tempering is used. Higher-grade blades are then treated with a compound such as liquid nitrogen at -100°C for the time necessary to prevent later deformation of structures where martensitic transformation has not been completed (residual austenite). This is called sub-zero processing